Tighten the two strum box fixing screws.

Turn the engine support into horizontal position.

Place the left crankcase half on the engine support, fitting it on the engine support pins.

Caution! Take particular care to ensure that the engine and engine mounting are stable and ensure that the engine is securely fastened to the mounting plate.

Fit the complete transmission gears unit.

Apply black sealing paste (Threebond) on the left crankcase half.

Caution! Be careful not to apply THREEBOND in excess as it may block oil ducts through the crankcase halves.

Place the right crankcase half with the aid of a rubber hammer.

Tighten the two fixing pins.

Rotate the engine and the engine support into vertical position.

Working on the left side, place the nine M6 screws fixing the crankcase.

Working on the left side, place the nine M8 screws fixing the crankcase.

Tighten all the crankcase fixing screws, both M6 and M8 type.

Slide in the clutch control rod.

Place the pinion.

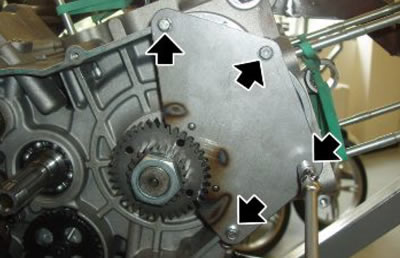

Place the gear selector drum and check that it is correctly timed; thrust the desmo drum axially from the flywheel side so that the timing roller protrudes.

Tighten the gear selector drum fixing screw.

Position the tone wheel.

Tighten the tone wheel with the special tool.

Use Loctite medium-strength for sealing.

- Specific tooling: 020715Y Tone wheel removal

Tighten the pinion fixing nut using the special tool.

- Specific tooling: 9100896 Clutch bell locking tool

Position the sensor contact together with the spring.

Place the neutral sensor and lubricate its seat to facilitate refitting.

Caution! Be careful not to damage the o-ring when inserting the sensor in its position.

Tighten the two screws fixing the neutral sensor.

Position the plate together with the selector.

Tighten the three screws fixing the gear selector plate by applying Loctite medium-strength.

Place the speed sensor with caution.

Tighten the speed sensor fixing screw.

Place the transmission control rod with the washer.

Remove the grease off the primary pinion tapered pins - crankshaft coupling surfaces.

Position the crankshaft gear.

Position the washer and the crankshaft lock-nut.

Fit the special tool and fix it steadfastly to the crankcase by tightening the four fixing screws on the crankcase.

Tighten the crankshaft gear lock-nut.

- Specific tooling: 020711Y Engine pinion locking