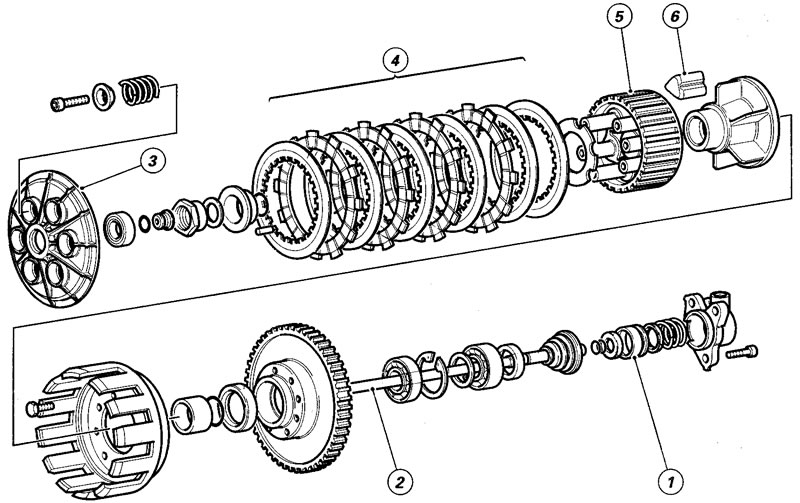

The clutch is disengaged using a drive unit consisting of a thrust piston (1) which operates inside a support, connected to the alternator cover. This piston (1) pushes a control rod (2), fitted in the primary gearbox shaft which, in turn, drives the plate pusher (3), located at the end of the plate pack (4).

The motion from the drum (5) to the primary shaft is transmitted using special rubber cush drive pads (6) which soften the engagement of the clutch and prevent harmful kickback on the drive parts.

Before operating on the internal clutch parts, check for any functioning problems. Then deal with these problems in a systematic manner.

The following is a list of possible causes of clutch malfunctioning.

A clutch which does not disengage may be caused by:

- excessive play of the control lever;

- distorted clutch plates;

- incorrect spring tension;

- degraded engine oil;

- excessive quantity of oil in the block; faulty clutch mechanism;

- excessive wear of the drum or clutch housing.

A clutch which slips may be caused by:

- insufficient play of the control lever;

- worn clutch plates;

- weakened springs;

- faulty clutch mechanism;

- excessive wear of the drum or clutch housing.

A noisy clutch may be caused by:

- excessive play between the primary drive gears;

- damaged primary drive gear teeth; excessive play between drive plate end parts and clutch housing;

- worn gear/clutch housing support bearings;

- the presence of metal particles (filings) on the gear teeth.

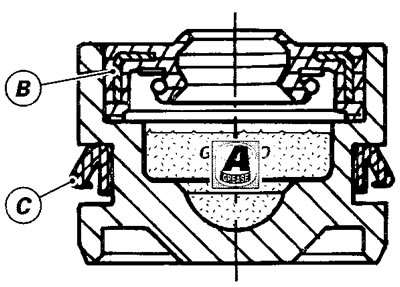

Clutch drive unit

Check that the control rod is straight by turning it on a reference surface. The deviation must not exceed 0.3 mm/0.0012 in.

Check the state of wear of the inner seal ring (B) and the outer scraper ring (C).

Before refitting, fill the inner groove of the piston with grease.

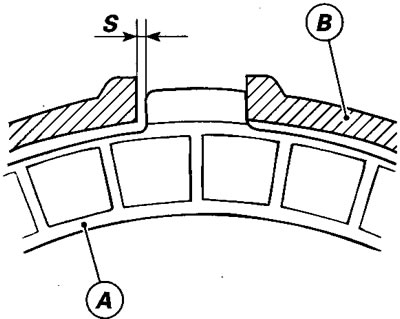

Clearance between clutch housing and drive plate

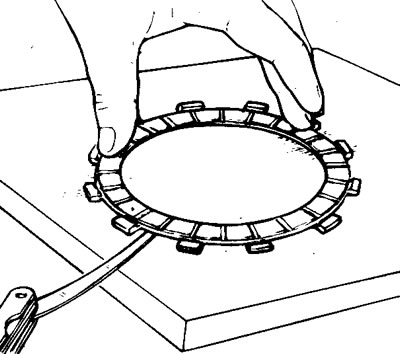

Insert the drive plate (A) in the clutch housing (B) and measure the clearance (S) with a feeler gauge:

The clearance (S) must not exceed 0.6 mm/0.023 in.

If it does, change the plates and, if necessary, the clutch housing.

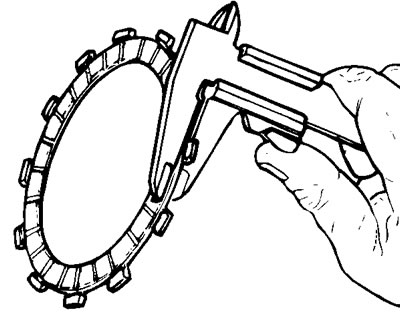

Clutch plates

The clutch plates must not show any signs of burning, grooves or deformation.

Measure the thickness of the drive plates (the ones with friction material): it must be at least 2.5 mm/0.084 in.

Caution! The total thickness of the clutch plate pack must be at least 36.5 mm/1.437 in.

Place the drive and driven plates on a flat surface and check the amount of deformation with a feeler gauge.

Limit: 0.2 mm/0.008 in.

Clutch springs

Measure the clear length "L" of each spring with a caliper gauge;

It must not exceed 36.5 mm/1.437 In.

Change all springs which do not comply.