Outline

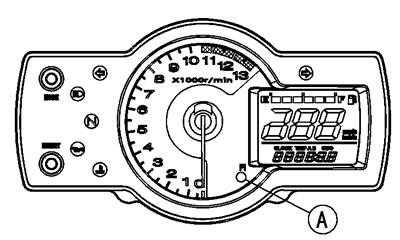

When an abnormality in the DFI system occurs, the FI indicator light (LED) goes on to alert the rider on the meter panel. In addition, the condition of the problem is stored in the memory of the ECU (electronic control unit). With the engine stopped and turned in the self-diagnosis mode, the service code [A] is indicated by the number of times the FI indicator light (LED) blinks.

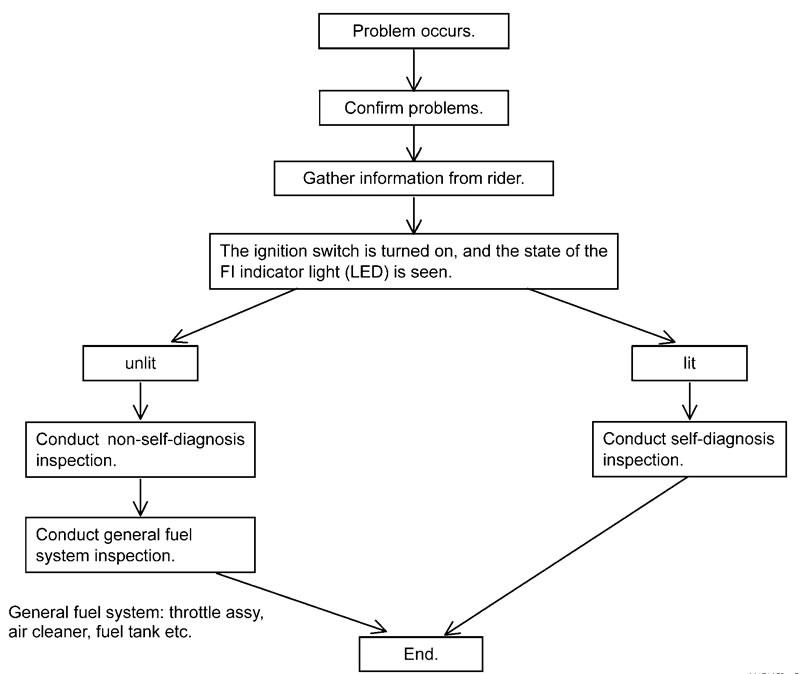

When due to a malfunction, the FI indicator light (LED) remains lit, ask the rider about the conditions [B] under which the problem occurred and try to determine the cause [C].

First, conduct a self-diagnosis inspection and then a non-self-diagnosis inspection. The non-self-diagnosis items are not indicated by the FI indicator light (LED). Don't rely solely on the DFI self-diagnosis function, use common sense.

Even when the DFI system is operating normally, the FI indicator light (LED) [A] may light up under strong electrical interference. No repair needed. Turn the ignition switch OFF to stop the indicator light.

When the FI indicator light (LED) goes on and the motorcycle is brought in for repair, check the service codes.

When the repair has been done, the light (LED) doesn't go on. But the service codes stored in memory are not erased to preserve the problem history, and the light (LED) can display the codes in the self-diagnosis mode. The problem history is referred when solving unstable problems.

When the motorcycle is down, the vehicle-down sensor is turned OFF and the ECU shuts off the fuel injectors and ignition system. The FI indicator light (LED) blinks but the service code cannot be displayed. The ignition switch is left ON. If the starter button is pushed, the electric starter turns but the engine doesn't start. To start the engine again, raise the motorcycle, turn the ignition switch OFF, and then ON. The vehicle-down sensor is turned ON and the light (LED) goes OFF.

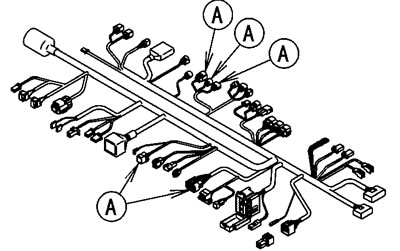

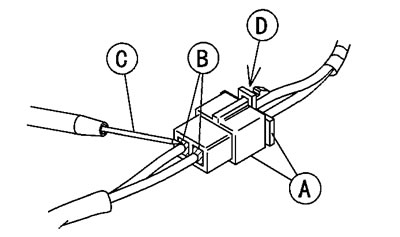

The DFI part connectors [A] have seals [B], including the ECU.

- Join the connector and insert the needle adapters [C] inside the seals [B] from behind the connector until the adapter reaches the terminal.

Special Tool - Needle Adapter Set: 57001-1457

Caution: Insert the needle adapter straight along the terminal in the connector to prevent short-circuit between terminals.

- Make sure that measuring points are correct in the connector, noting the position of the lock [D] and the lead color before measurement. Do not reverse connections of the hand tester or a digital meter.

- Be careful not to short-circuit the leads of the DFI or electrical system parts by contact between adapters.

- Turn the ignition switch ON and measure the voltage with the connector joined.

Caution: Incorrect, reverse connection or short circuit by needle adapters could damage the DFI or electrical system parts.

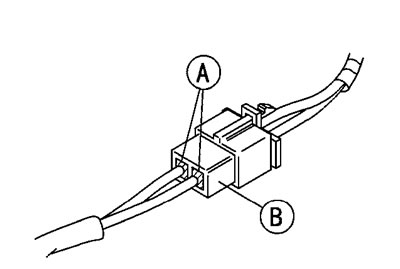

After measurement, remove the needle adapters and apply silicone sealant to the seals [A] of the connector [B] for waterproofing.

Sealant - Kawasaki Bond (Silicone Sealant): 56019-120

- Always check battery condition before replacing the DFI parts. A fully charged battery is a must for conducting accurate tests of the DFI system.

- Trouble may involve one or in some cases all items. Never replace a defective part without determining what CAUSED the problem. If the problem was caused by some other item or items, they too must be repaired or replaced, or the new replacement part will soon fail again.

- Measure coil winding resistance when the DFI part is cold (at room temperature).

- Make sure all connectors in the circuit are clean and tight, and examine wires for signs of burning, fraying, short, etc. Deteriorated wires and bad connections can cause reappearance of problems and unstable operation of the DFI system.

If any wiring is deteriorated, replace the wiring.

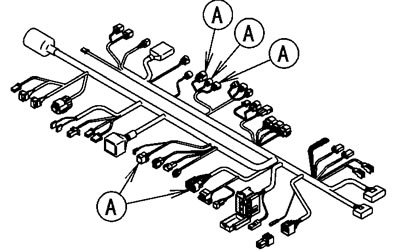

- Pull each connector [A] apart and inspect it for corrosion, dirt, and damage.

If the connector is corroded or dirty, clean it carefully. If it is damaged, replace it. Connect the connectors securely.

- Check the wiring for continuity.

Use the wiring diagram to find the ends of the lead which is suspected of being a problem.

Connect the hand tester between the ends of the leads.

Set the tester to the x 1 Q range, and read the tester.

If the tester does not read 0 Q, the lead is defective. Replace the lead or the main harness or the sub harness.

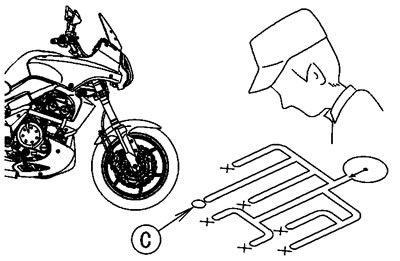

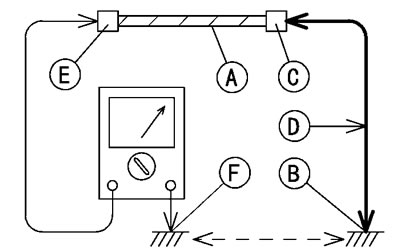

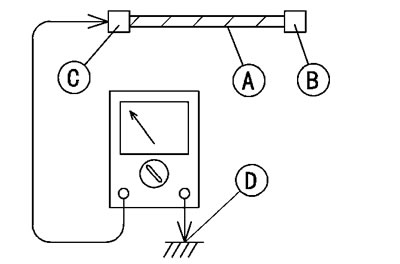

If both ends of a harness [A] are far apart, ground [B] the one end [C], using a jumper lead [D] and check the continuity between the end [E] and the ground [F]. This enables to check a long harness for continuity. If the harness is open, repair or replace the harness.

When checking a harness [A] for short circuit, open one end [B] and check the continuity between the other end [C] and ground [D]. If there is continuity, the harness has a short circuit to ground, and it must be repaired or replaced.

- Narrow down suspicious locations by repeating the continuity tests from the ECU connectors.

If no abnormality is found in the wiring or connectors, the DFI parts are the next likely suspects. Check the part, starting with input and output voltages. However, there is no way to check the ECU itself.

If an abnormality is found, replace the affected DFI part.

If no abnormality is found in the wiring, connectors, and DFI parts, replace the ECU.

Lead Color Codes:

- BK: Black

- BL: Blue

- BR: Brown

- CH: Chocolate

- DG: Dark Green

- G: Green

- GY: Gray

- LB: Light Blue

- LG: Light Green

- O: Orange

- P: Pink PU: Purple

- R: Red

- W: White

- Y: Yellow

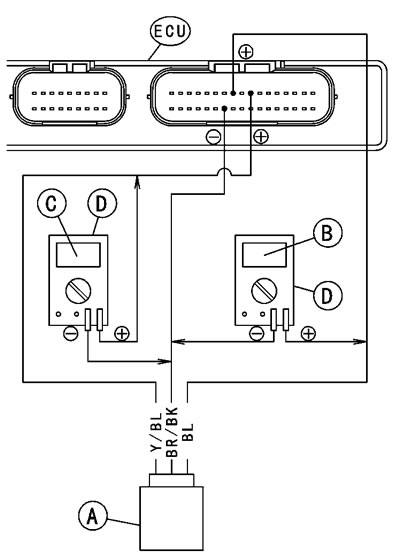

There are two ways to inspect the DFI system. One is voltage Check Method and the other is Resistance Check Method. (Voltage Check Method)

This method is conducted by measuring the input voltage [B] to a sensor [A] first, and then the output voltage [C] from the sensor.

Sometimes this method can detect a fault of the ECU.

- Refer to each sensor inspection section for detail in this chapter.

- Use a fully charged battery and a digital meter [D] which can be read two decimal places voltage or resistance. (Resistance Check Method)

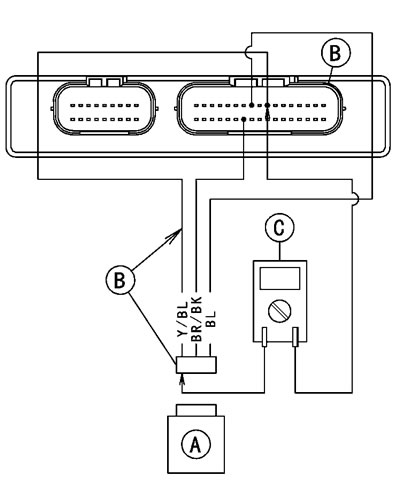

This method is simple. No need for a fully charged battery and the needle adapter. Just do the following especially when a sensor [A] is suspect.

- Turn the ignition switch OFF and disconnect the connectors.

- Inspect the sensor resistance, using a digital meter (see each sensor inspection).

- Inspect the wiring and connectors [B] for continuity, using the hand tester [C] (analog tester) rather than a digital meter.

Special Tool - Hand Tester: 57001-1394

If the sensor, the wiring and connections are good, inspect the ECU for its ground and power supply (See ECU Power Supply Inspection).

If the ground and power supply are good, the ECU is suspect. Replace the ECU.

DFI Diagnosis Flow Chart