Note: Valve clearance must be checked and adjusted when the engine is cold (room temperature).

Remove:

- Cylinder Head Cover (See Cylinder Head Cover Removal in the Engine Top End chapter)

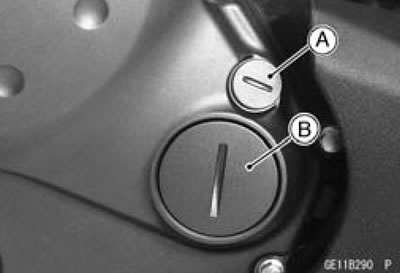

- Timing Inspection Cap [A]

- Timing Rotor Bolt Cap [B]

- Check the valve clearance when the pistons are at TDC.

- The pistons are numbered beginning with the engine left side.

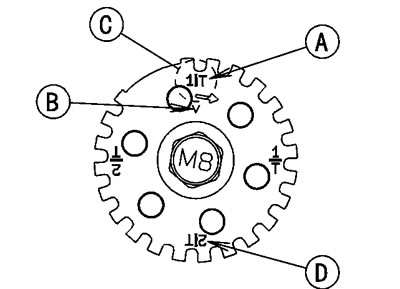

- Using a wrench on the timing rotor bolt, turn the crankshaft clockwise until the 1/T mark line [A] on the timing rotor is aligned with the notch [B] in the edge of the timing inspection hole [C] in the clutch cover for #1 piston and 2/T mark line [D] for #2 piston.

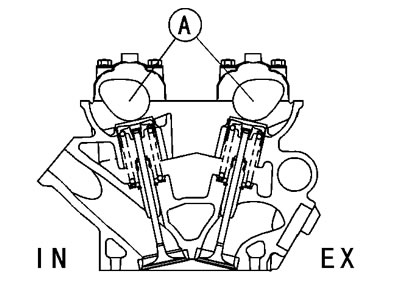

Measure the valve clearance of the valves for which the cams [A] are turned away from each other.

- Using the thickness gauge [A], measure the valve clearance between cam and valve lifter.

Valve Clearance

Standard:

- Exhaust 0.22-0.31 mm (0.0087-0.0122 in.)

- Inlet 0.15-0.21 mm (0.0059-0.0083 in.)

Each piston has two inlet and two exhaust valves. Measure these two inlet or exhaust valves at the same crankshaft position.

Note: Check the valve clearance using this method only. Checking the clearance at any other cam position may result in improper valve clearance.

Valve Clearance Measuring Position

#1 Piston TDC at End of Compression Stroke:

- Inlet valve clearances of#1 piston, and Exhaust valve clearances of #1 piston

#2 Piston TDC at End of Compression Stroke:

- Inlet valve clearances of#2 piston, and Exhaust valve clearances of #2 piston

If the valve clearance is not with in the specified range, first record the clearance, and adjust it.