Note: These procedures are explained on the assumption that the inlet and exhaust systems of the engine are in good condition.

- Situate the motorcycle so that it is vertical.

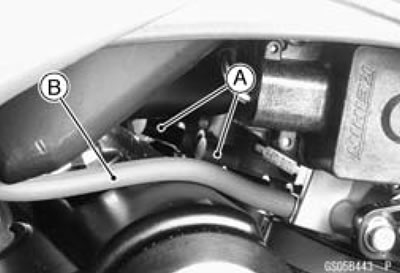

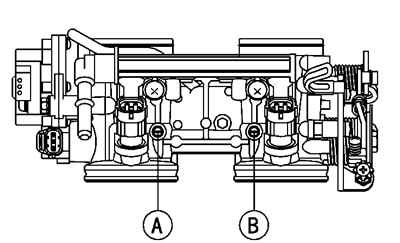

- Pull off the rubber caps [A] from the fitting of each throttle body.

Caution: Do not remove the inlet air pressure sensor hose [B] on the left fitting of the throttle body.

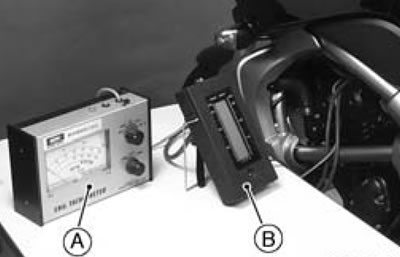

- Connect a vacuum gauge (special tool) and hoses [A] to the fittings of the throttle body as shown.

Special Tool - Vacuum Gauge: 57001-1369

- Connect a highly accurate tachometer to one of the stick coil primary leads.

- Start the engine and warm it up thoroughly.

- Check the idle speed, using a highly accurate tachometer [A].

- Open and close the throttle.

If the idle speed is out of the specified range, adjust it.

Caution: Do not measure the idle speed by the tachometer of the meter unit.

- While idling the engine, inspect the engine vacuum, using the vacuum gauge [B].

Engine Vacuum

Standard: 37.9±1.3 kPa (285±10 mmHg) at Idle Speed 1 300±50 r/min (rpm)

If any one vacuum is not within the specification, turn in the bypass screws until it seats fully but not tightly.

Special Tool - Pilot Screw Adjuster, E [A]: 57001-1603

Caution: Do not overtighten them. They could be damaged, requiring replacement.

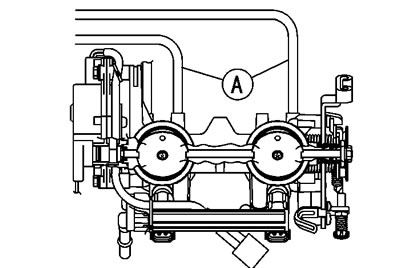

- Turn out the bypass screw of the higher vacuum between #1 [A] and #2 [B] to the lower vacuum.

- Open and close the throttle valves after each measurement and adjust the idle speed as necessary.

- Inspect the vacuums as before.

If both vacuums are within the specification, finish the engine vacuum synchronization.

If any vacuum can not be adjusted within the specification, remove the bypass screws #1, #2 and clean them.

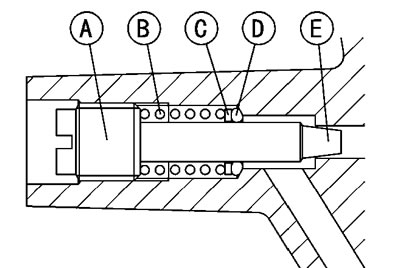

- Remove the bypass screw [A], spring [B], washer [C] and O-ring [D].

Check the bypass screw and its hole for carbon deposits.

If any carbon accumulates, wipe the carbon off the bypass screw and the hole, using a cotton pad penetrated with a high-flash point solvent.

Replace the O-ring with a new one.

Check the tapered portion [E] of the bypass screw for wear or damage.

If the bypass screw is worn or damaged, replace it.

- Turn in the bypass screw until it seats fully but not tightly.

- Repeat the same procedure for other bypass screws.

- Repeat the synchronization.

If the vacuums are correct, check the output voltage of the main throttle sensor (See Main Throttle Sensor Output Voltage Inspection in the Fuel System (DFI) chapter).

Special Tool - Throttle Sensor Setting Adapter: 57001-1538

Main Throttle Sensor Output Voltage Connections to Adapter

- Meter (+) → R (Sensor Y/W) lead

- Meter (-) → W (Sensor BR/BK) lead

Standard: DC 1.005-1.035 V (at idle throttle opening)

If the output voltage is out of the range, check the throttle input voltage (See Main Throttle Sensor Input Voltage Inspection in the Fuel System (DFI) chapter).

- Remove the vacuum gauge hoses and install the vacuum hoses and rubber caps.