Removal

1. Remove the engine from the frame (see page 10.2).

2. Separate the lower and upper crankcases (see page 5.5).

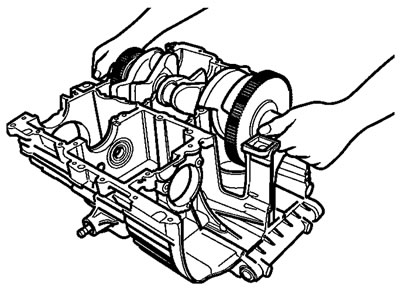

3. Lift the balancer out of the upper crankcase.

Removing the balancer

4. Remove the connecting rod big end caps (see page 5.10). Discard the bolts after removal.

5. Lift the crankshaft from the upper crankcase. Support the connecting rods during crankshaft removal to prevent damage to the rods, liners and upper crankcase.

Removing the crankshaft

Installation

Caution! Always check the main bearing journal clearance (see page 5.13), before final assembly of the crankshaft. Failure to correctly select crankshaft bearings will result in severe engine damage.

1. Select and fit new main and big end bearing shells using the selection processes detailed on pages 5.12 and 5.13.

2. Lubricate all bearings with engine oil.

3. Ensure that the crankshaft is clean, and that the oil ways within the crankshaft are clean and free from blockages and debris.

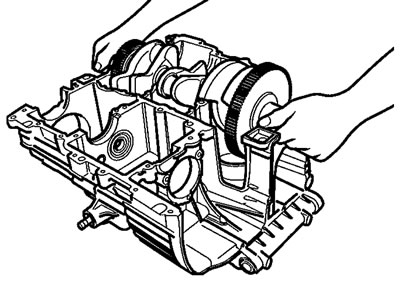

4. Install the crankshaft ensuring that the crankpins align with the corresponding big ends.

Installing the crankshaft

5. Align the connecting rod big ends to the crankpins.

6. Fit the big end caps and tighten them (see page 5.10 for the tightening sequence and torque).

7. Install the balancer (see page 7.4).

8. Assemble the crankcases (see page 5.7).