System description

This model is fitted with an electronic anti-lock brake system which is designed to prevent the wheels from locking or skidding by reducing braking effort to the front or rear brake caliper as required.

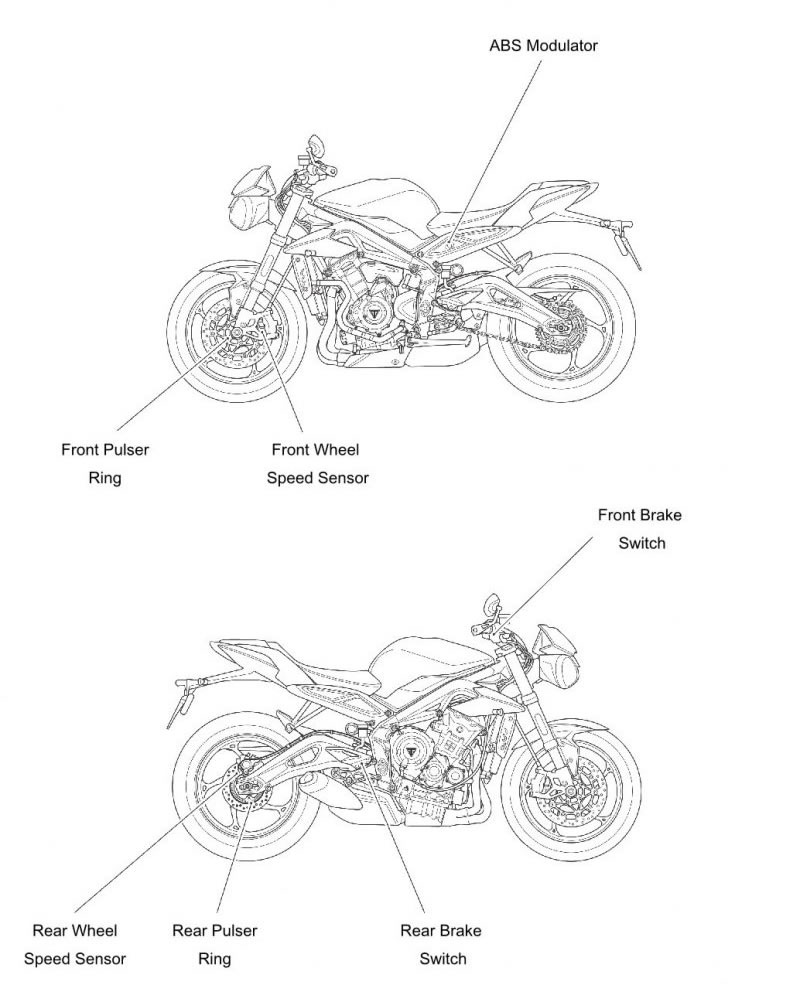

The system consists of a hydraulic modulator and ECM assembly mounted to a bracket beneath the riders seat, a front wheel speed sensor mounted to the front fork, and a rear wheel speed sensor mounted to the rear brake caliper carrier.

Both front and rear wheels have a pulser ring mounted on to the wheel hub.

The front and rear master cylinders are connected via lines to the modulator and from the modulator the lines connect to the brake calipers.

The front and rear brake circuits operate as separate systems. The front and rear brakes are not connected in any way inside the modulator.

The modulator ECM continuously calculates the front and rear wheel speeds, and from these inputs the ECM calculates the estimated motorcycle speed, wheel deceleration/acceleration, the wheel speed difference and the wheel slip (skid) rate. This is calculated by comparing the calculated wheel speeds with the calculated vehicle speed, so that if one wheel speed deviates significantly from the other two readings, this wheel is calculated to be slipping (skidding).

Under braking, if the modulator detects that either wheel is about to slip, due to the brake force exceeding the available traction between the tyre and road surface (the wheel will begin to slip or 'skid'), the ECM very rapidly releases and reapplies the brake pressure to prevent the wheel from slipping.

This is felt through the brake pedal or lever as a rapid 'pulsing'.

If the rider reduces braking effort, or traction increases (so that traction exceeds braking force, the wheel will rotate once more) the wheel will no longer lock up. The ABS system will detect this and stop controlling brake pressure, and return to its monitoring state.

The system has a self diagnostic function built-in which monitors the fail safe relay, solenoid valves, motor relay, wheel speed sensors, power supply and ground, as well as internal ECM functions. In the event of a malfunction being detected, the ECM will illuminate the ABS warning light, and store a diagnostic trouble code in the system memory. This stored data can then be recovered using the Triumph Diagnostic Tool which is mandatory for all Triumph dealers. In this way, precise diagnosis of a fault can be made and the fault quickly rectified.

Under normal operation, the ABS warning light will flash after the ignition is switched on and until the vehicle speed exceeds 6 mph (10 km/h). The ABS performs a self check and if no faults are found the flashing light is extinguished. If a trouble code is stored the ABS warning light will stay illuminated and the ABS will not function, however the brakes will operate as a non-ABS braking system. If the ABS warning light does not extinguish, or illuminates whilst the motorcycle is being ridden, refer to the ABS system diagnostics (see System Diagnostics).

Warning!

- The ABS warning light will illuminate when the rear wheel is driven at high speed for more than 30 seconds when the motorcycle is on a stand, or driven on a dynamometer. This reaction is normal.

- When the ignition is switched off and the motorcycle is restarted, the warning light will illuminate until the motorcycle reaches a speed exceeding 19 mph (30 km/h) when it will go off.

- Diagnostic Trouble Code (DTC) C1612 will remain stored in the ABS ECM memory for 40 ignition cycles before being deleted (see Diagnostic Trouble Codes).

ABS component locations