Remove needle roller.

Swivel engine in assembly fixture so that magnet side is uppermost.

Remove all threaded fasteners for engine housing.

Remove oil filter and unfasten two fasteners on base plate for engine housing.

Swivel assembly fixture so that clutch side is uppermost.

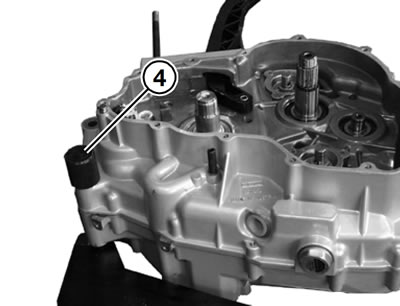

Remove knurled nuts (4).

Caution: Do not tilt engine housing: this can cause damage to bearing shell.

Raise the engine housing at the left and strike the mainshaft, countershaft and balancing shaft alternately with light blows of a plastic-faced hammer, so that these remain in the magnet side.

Screw knurled nut on to engine support with spacer.

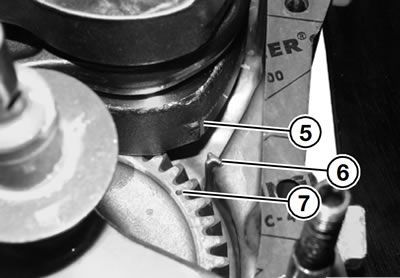

Align marks (7) on balancing shaft and crankshaft (5) with mark on housing (6).

Note: Note shims on crankshaft.

First lift out crankshaft, then balancing shaft.

Checking crankshaft for wear

Check bearing journal on crankshaft and conrod for signs of damage and wear.

- Bearing journal dia: min. 45.97 mm (1.810 in)

- Radial play, main bearing: max. 0.10 mm (0.004 in)

- Endplay, conrod/crankshaft webs: max. 0.80 mm (0.031 in)

- Small end bore dia: max. 22.04 mm (0.868 in)