Note: Clean the threads in the housing neck prior to assembly.

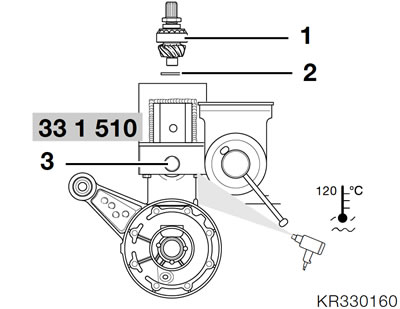

- Secure the housing centrally in holder, BMW No. 331510, using bearing stud (3).

Caution: Make sure that the grub screws do not project as otherwise the neck of the housing could be damaged.

- Seat the grub screws in holder, BMW No. 331510.

- Using holder, BMW No. 33 1 510, clamp the housing upright as illustrated.

- Insert shim (2) into neck of housing.

- Chill input bevel pinion prior to installation in re-frigerator/freezer, or similar.

- Heat bearing seat to 120°C (248°F).

Note: When inserting input bevel pinion (1), make sure that it is not tilted.

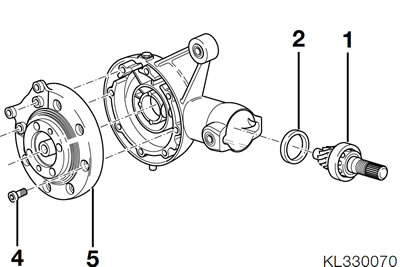

- Insert input bevel pinion (1) into housing.

- Install housing cover (5).

- Tighten fasteners (4) in diagonally opposite sequence.

Tightening torques:

- Housing cover to housing — 35 Nm

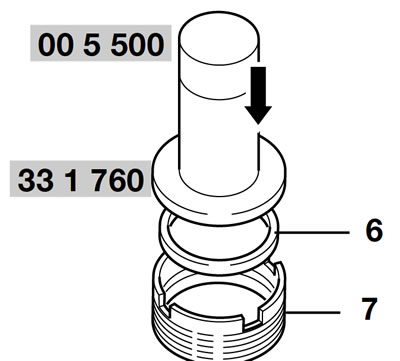

- Clean threads of threaded ring (7).

Caution: Install shaft sealing ring (6) with the sealing lips facing the input bevel pinion.

- Oil shaft sealing ring (6) lightly and drive into threaded ring (7) with drift, BMW No. 33 1 760, and handle, BMW No. 00 5 500.

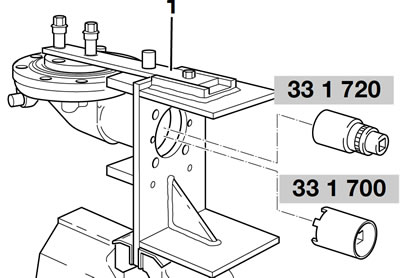

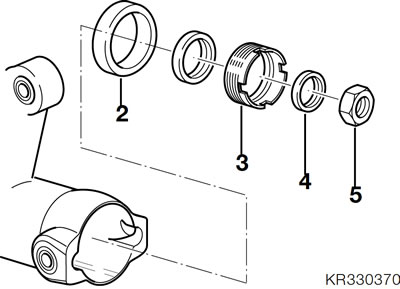

- Attach locking arm (1).

- Insert outer race (2).

- Coat threaded ring (3) with Hylomar SQ 32.

- Tighten threaded ring (3) with pin wrench, BMW No. 33 1 700.

- Oil thrust ring (4) lightly and place in position.

- Make sure that the lip of the shaft seal is seated correctly on the thrust ring.

- Clean the threads of hex nut (5).

- Coat the thread of hex nut (5) with Loctite 270.

Caution: Make sure that the nut does not damage the shaft sealing ring.

- Keep thread-locking compound well clear of splined shaft: wipe off all deposits immediately.

- Tighten hex nut (5) with 36 mm (1.4 in) socket wrench insert and reducing adapter, BMW No. 331720.

Tightening torques:

- Threaded ring (clean thread + Hylomar SQ 32) — 118 Nm

- Nut for input bevel pinion (clean thread + Loctite 270) — 200 Nm

- Housing cover — 35 Nm