Cleaning components

All metal components must be cleaned with fuel and dried with compressed air.

Warning! Inflammable fumes are created and metal particles may be thrown out by the engine during cleaning. Therefore, work in a room free from naked flames or sparks. Always wear safety goggles.

Couplings

For ideal functioning of the engine, all the couplings must be within the tolerances prescribed by the Manufacturer. In fact, a «tight" fit can cause dangerous seizure as soon as the moving parts heat up. A «loose" fit can cause vibrations which, as well as being noisy, can cause rapid wear of the moving parts.

Gaskets

The engines are fitted using a "THREE BOND 1215" liquid seal available from our Spare Parts Department in 50 ml packages with code number 94247.0014.

Before using the gaskets, the coupling surfaces must be greased and all traces of old gaskets must be eliminated.

Spread the liquid on one of the contact surfaces, avoiding the holes. Then make the couplings and remove all access liquid.

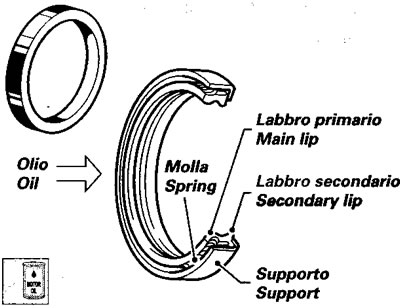

Oil seals

Change the oil seals every time the engine is overhauled.

Fit the new oil seals in their seats, ensuring that they are in square. Use suitable pads.

Then lubricate the lip of the oil seals with oil. This must be done very carefully.

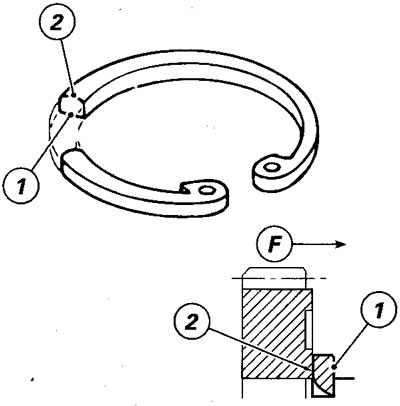

Circlips

Note. Change all circlips which are deformed or which have lost their original spring.

All the circlips have a side (1) which is completely flat and has a sharp edge and a side (2) with a slightly rounded edge.

When fitting the rings in the shaft grooves (e.g. in the gearbox shaft splines) the side (1) with the sharp edge must always be opposite the side force (F) created by the stop element (e.g. the gears).

Bearings

Wash the bearings thoroughly with fuel and dry them with compressed air. Do not turn them.

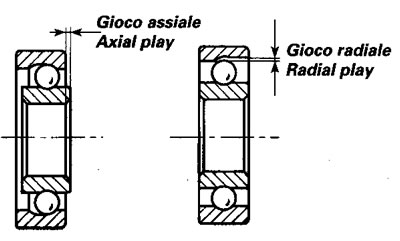

Lubricate them slightly and slowly turn the inner ring by hand; there must not be any obstructions to the rotation, hard spots or excessive play.

Note. Change the bearings every time the engine is overhauled.