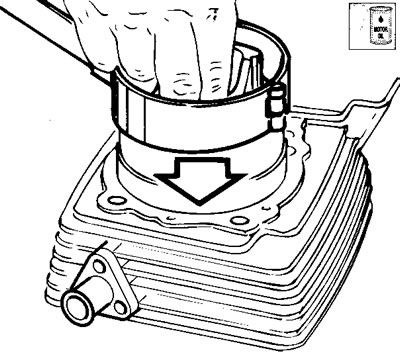

Use a universal tool, positioned as shown in the diagram, to carefully insert the piston inside the cylinder (first lubricate the inside of the cylinder with engine oil). Position the piston with the writing "A" facing the Intake port and "S" facing the exhaust port.

Degrease and clean any deposits from the contact surfaces of the crankcase half and the cylinders.

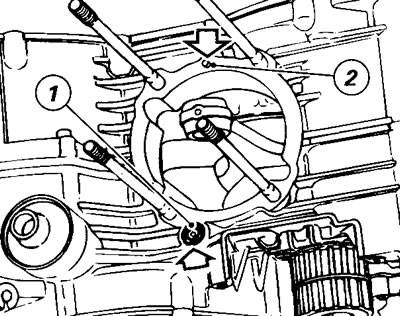

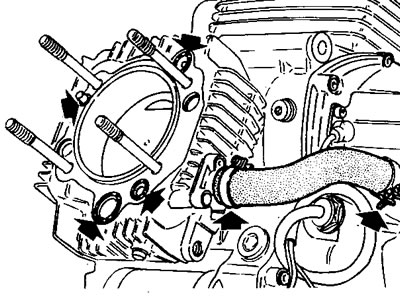

Insert the greased O-ring (1, diameter 9.25x1.78 mm) in the seat on the contact surface of the vertical cylinder with the block.

Check that the cylinder centring set screws (2) are fitted on the block.

Apply a layer of "THREE BOND" on both sides and fit the gaskets on the stud bolts on the block, positioning them as shown in the diagram.

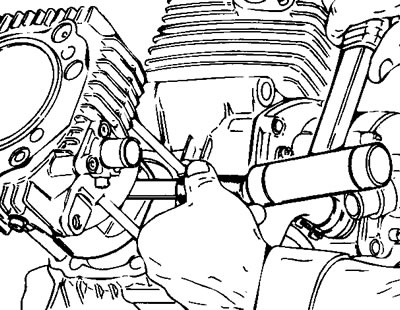

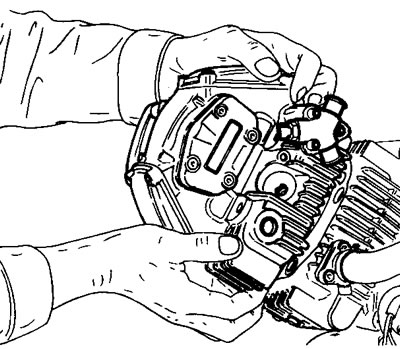

Insert the piston-cylinder assembly on the crankcase stud bolts.

Bring the connecting rod small end to the top dead center inside the piston, at the dudgeon pin hole.

Push the gudgeon pin to the end of the opposite circlip.

Plug the crankcase opening and insert the other circlip.

Push the cylinder downwards so that it touches the crankcase block.

Refit the cylinder - water pump connection manifolds and secure them with the clips at the openings.

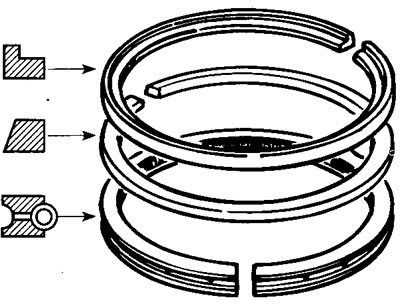

Position the greased seal rings (A, В, C) and the bushes (D) in the seats of the vertical and horizontal cylinders, following the indications in the table and the diagram:

| ref. | qty | size (mm) |

| A | 5 | diameter: 11.91x2.62 |

| В | 2 | diameter: 20.29x2.62 |

| C | 2 | diameter: 7.66x1.78 |

Insert the complete cylinder head on the crankcase stud bolts until it stops against the cylinder.

Insert the special washers on the stud bolts; the bevelled edge surface must be facing outwards and the flat side must be facing inwards.

Grease the threaded ends of the stud bolts with the recommended grease.

Tighten the head nuts, working diagonally. Use the special spanner 88713.1139 with a torque wrench. The force on the handle of the torque wrench must be perpendicular to the other spanner.

Tighten the bolts at the specified torque in three steps (see the table at the end of this section):

After running-in, tighten again at the final torque setting.

Caution! Failure to follow this procedure may lead to irregular elongation of the stud bolts and cause serious damage to the engine.