Note: Always install new engine-side and gearbox-side sealing rings for starter motor.

Use one hand to press the starter motor profiled sealing ring on the gearbox side into its groove.

- Install sealing rings.

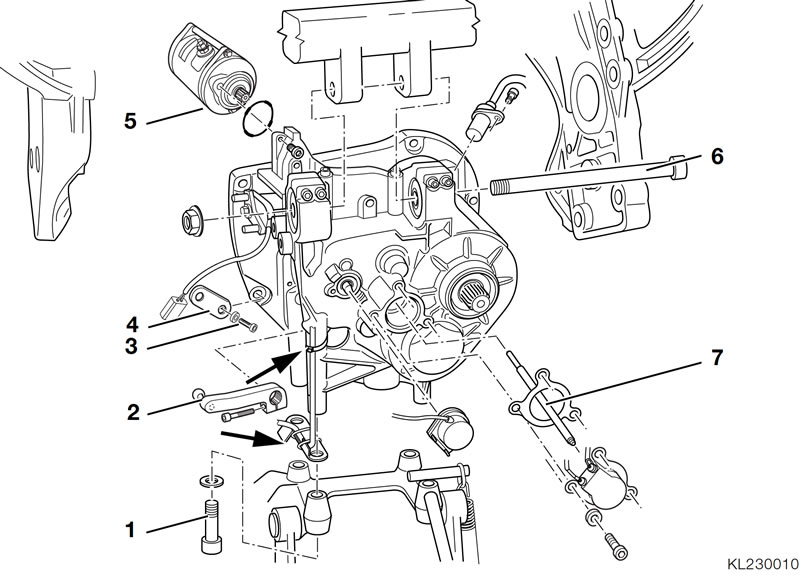

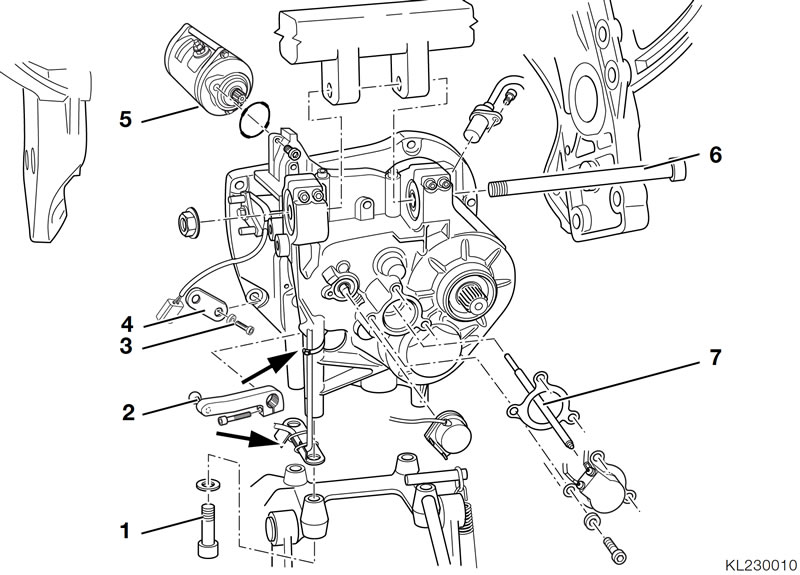

- Introduce starter motor (5) into bore in crankcase.

Note: If not removed, the main (centre) stand must be retracted to permit installation of the gearbox.

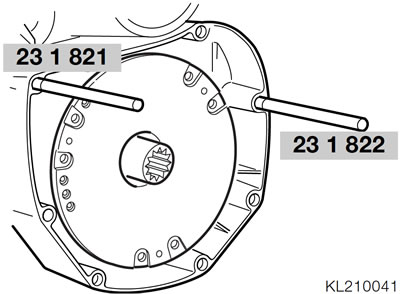

- Secure guide pins, BMW No. 23 1 820, to intermediate flange.

- Apply a coat of Optimoly MP 3 to the splines of the gearbox input shaft.

- Slide gearbox over guide pins, BMW No. 23 1 820, and into position on sleeves of intermediate flange.

Caution: Make sure that pinion of starter motor is correctly meshed with reverser.

- Remove guides, BMW No. 23 1 820.

Note: Apply Loctite 243 to threads of screw (3).

- Position link (4) for reverser against gearbox housing.

- Install screw (3) with threads coated with Loctite 243.

- Tighten all seven screws securing gearbox to intermediate flange.

Caution: To prevent the clutch slave cylinder from tilting, tighten three securing screws alternately and uniformly.

- Install clutch release rod.

- Clean mating surfaces on the gearbox housing and clutch slave cylinder, use new paper gasket.

- Install the clutch slave cylinder.

- Lower frame until cables can be connected to starter motor and generator and reconnect cables.

- Connect power cable for starter motor to terminal on rear frame, use cable ties to secure cables.

- Fully lower the frame.

- Insert gearbox mounting bolt (6) and tighten.

- Insert clutch release rod (7) into gearbox, noting correct installed position.

- Connect selector lever (2) to gearshift linkage.

- If necessary, install screws (1) securing bearing mount to main stand.

- Secure cable for side stand switch to gearbox with cable tie (arrow).

Caution: The alignment of the left-hand rubber mounts relative to the frame is preset at the factory; do not slacken the securing screws.

The rubber mounts do not have to be re-aligned unless the left-hand rubber mount has been replaced.

Note: When lowering the frame, make sure that clearance is adequate on the right between frame and gearbox: do not scratch the surfaces.

- Secure the left/right engine mountings to the cross-member.

- Fully lower the frame.

- Remove workshop crane, BMW No. 46 5 640.

- Install skirt brackets.

- Connect plugs for oxygen sensor, side-stand switch, and coolant-temperature sensor.

- Install actuating unit for reverser, complete with switch unit.

- Install radiators with fans left and right in holders.

- Reconnect plugs and cables for engine and gearbox.

- Install transverse tube.

- Install front drive shaft.

- Install swinging arm.

- Install rear wheel drive.

- Install brake caliper.

- Install inductive sensor for rear wheel drive.

- Install rear wheel.

- Install exhaust system.

- Install left and right battery covers.

- Install left and right rear footrest plates.

- Fill gearbox with oil to correct level.

- Install left and right front footrest plates.

- Install throttle-valve rail with air filter box.

- Install fuel injection rail.

- Install the intake air pipe.

- Install the fuel tank.

- Install tank cover with the control unit for the radio.

- Remove lifting gear, BMW No. 00 1 510.

- Install engine spoiler.

- Install actuating control for reverser.

- Install left and right fairing side sections.

Caution: Connect the positive battery terminal first, then the negative terminal.

- Install the battery.

Quantities:

- Initial filling — approx. 0.6...0.75 (1.06...1.32 Imp. pint/0.63...0.79 US quarts)

- Oil changes — top up oil to bottom of filler neck

Tightening torques:

- Oil drain plug — 55 Nm

- Oil filler/level check plug — 23 Nm

- Selector lever to selector shaft — 9 Nm

- Reverser shift lever to gearbox — 9 Nm

- Gearbox to intermediate flange M8 — 24 Nm

- Link, reverser actuator to intermediate flange M8 (clean thread and Loctite 243) — 24 Nm

- Starter motor to gearbox — 6 Nm

- Gearbox to frame — 70 Nm

- Pinch bolts, rubber mounts — 9 Nm

- Speed sensor for reverser — 6 Nm

- Slave cylinder to intermediate flange — 9 Nm

- Cross-members to engine — 41 Nm

- Pivot mount to gearbox — 41 Nm

- Actuating control, reverser (clean thread and Loctite 243) — 6 Nm

- Footrest plate to frame — 21 Nm

- Cover plate, reverser, to gearbox (clean thread and Loctite 243) — 10 Nm

- Cover of reverser to gearbox — 10 Nm