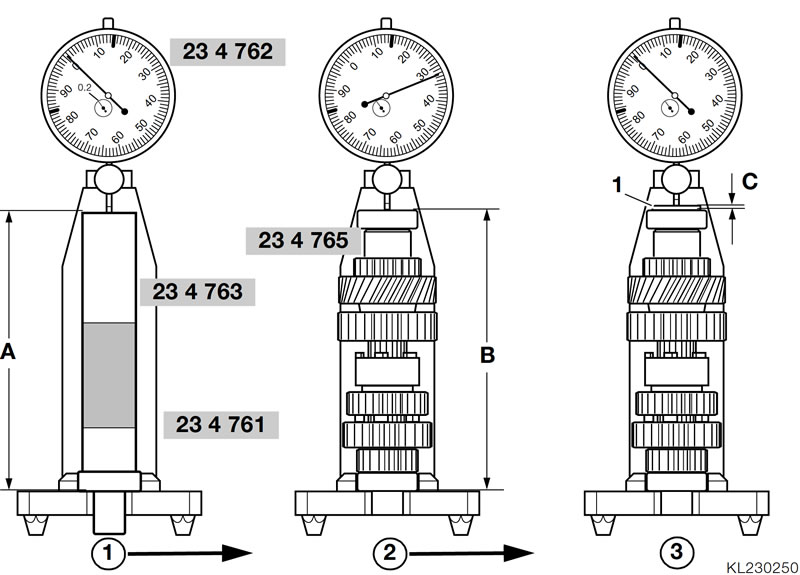

Checking/adjusting fully assembled length of intermediate shaft

Caution: Check and adjust the fully assembled length as described below and install a spacing washer of the correct thickness.

Before measuring, always make sure that the grooved ball bearings are pressed fully home, even if the shaft has not been disassembled and reassembled.

- Pull off the input-side grooved ball bearing with universal puller, BMW No. 007500.

- Remove the spacing washer.

- Locate dial gauge, BMW No. 23 4 762, in rear bore of measuring fixture, BMW No. 23 4 761, and set to 0.2 mm (0.008 in) preload.

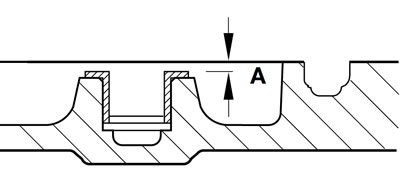

- Using dial gauge, zero to distance "A" of the zero gauge, BMW No. 23 4 763.

- Place reference washer, BMW No. 23 4 765, on the intermediate shaft.

- Place the grooved ball bearing on the reference washer.

- Insert intermediate shaft in measuring stand.

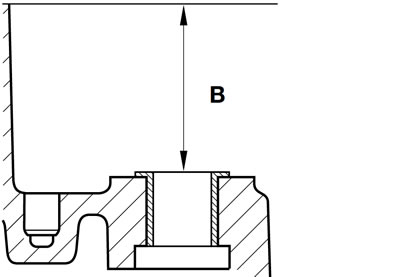

- Using the dial gauge, measure the deviation from zero of distance "B" at the inner bearing race.

Deviation from zero is equivalent to the thickness "C" of spacer (1).

- Place spacer (1) of correct thickness on inner bearing race and check deviation from zero.

A = B + C

Caution: The maximum deviation from zero must not be exceeded.

- Remove the intermediate shaft from the measuring fixture.

- Take off spacer, grooved ball bearing and reference washer.

- Place a spacing washer (1) of the correct thickness on the intermediate shaft and press on the grooved ball bearing.

Reference dimension for intermediate shaft:

- Maximum deviation from zero — -0.05...0.00 mm (-0.002...0.00 in)

- Fully assembled length — 198.95...199.00 mm (7.833...7.835 in)

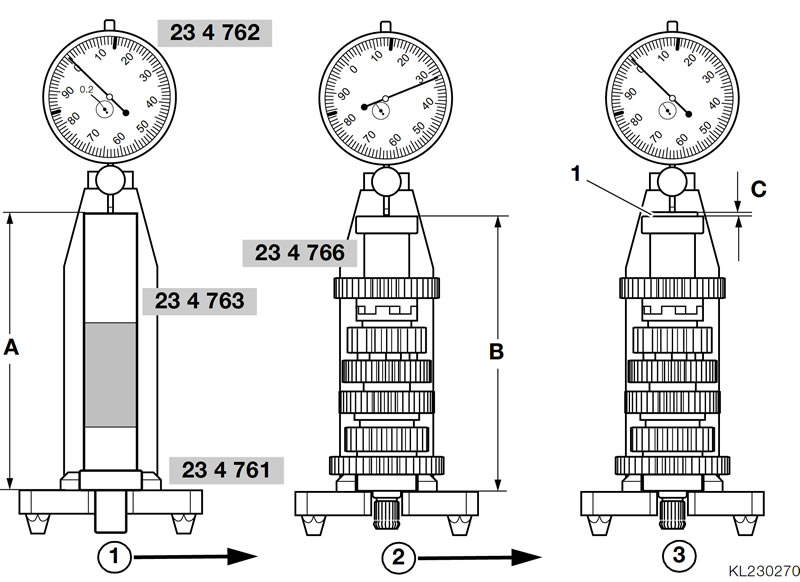

Checking/adjusting fully assembled length of output shaft

Caution: Check and adjust the fully assembled length as described below and install a spacing washer of the correct thickness.

Before measuring, always make sure that the grooved ball bearings are pressed fully home, even if the shaft has not been disassembled and reassembled.

- Pull off output-side deep-groove ball bearing with universal puller, BMW No. 00 7 500.

- Remove the spacing washer.

- Locate dial gauge, BMW No. 23 4 762, in rear bore of measuring fixture, BMW No. 23 4 761, and set to 0.2 mm (0.008 in) preload.

- Using dial gauge, zero to distance "A" of the zero gauge, BMW No. 23 4 763.

- Place reference washer, BMW No. 23 4 766, on the output shaft.

- Place the grooved ball bearing on the reference washer.

- Insert the output shaft into the measuring stand.

- Using the dial gauge, measure the deviation from zero of distance "B" at the inner bearing race.

- Deviation from zero is equivalent to the thickness "C" of spacer (1).

- Place spacer (1) of correct thickness on inner bearing race and check deviation from zero.

A = B + C

Caution: The maximum deviation from zero must not be exceeded.

- Take off spacer, grooved ball bearing and reference washer.

- Place a spacing washer (1) of the correct thickness on the output shaft and press on the grooved ball bearing.

Reference dimension for output shaft:

- Maximum deviation from zero — -0.05...0.00 mm (-0.002...0.00 in)

- Fully assembled length — 192.95...193.00 mm (7.596...7.598 in)

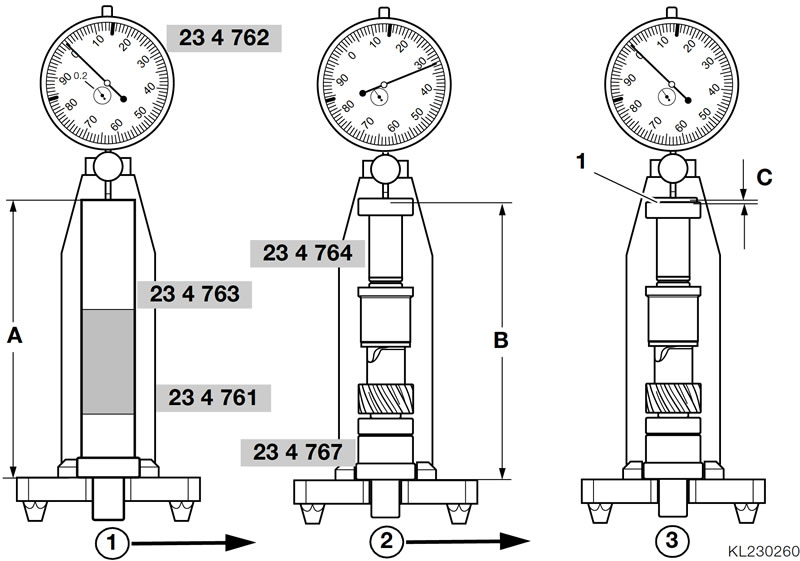

Checking/adjusting fully assembled length of input shaft

Caution: Check and adjust the fully assembled length as described below and install a spacing washer of the correct thickness.

Before measuring, always make sure that the grooved ball bearings are pressed fully home, even if the shaft has not been disassembled and reassembled.

- Pull off output-side deep-groove ball bearing with universal puller, BMW No. 00 7 500.

- Remove the spacing washer.

- Locate dial gauge, BMW No. 23 4 762, in front bore of measuring fixture, BMW No. 23 4 761, and set to 0.2 mm (0.008 in) preload.

- Using dial gauge, zero to distance "A" of the zero gauge, BMW No. 23 4 763.

- Mount reference washer, BMW No. 23 4 764, on the input shaft.

- Place the grooved ball bearing on the reference washer.

- Insert input shaft with adapter disc, BMW No. 234767, in measuring stand.

- Using the dial gauge, measure deviation from zero of distance "B" at the inner bearing race.

- Deviation from zero is equivalent to the thickness "C" of spacer (1).

- Place spacer (1) of correct thickness on inner bearing race and check deviation from zero.

A = B + C

Caution: The maximum deviation from zero must not be exceeded.

- Take the input shaft out of the measuring fixture.

- Remove the adapter disc, spacing washer, grooved ball bearing and reference washer.

- Place spacer (1) of the correct thickness in position and press the grooved ball bearing onto the input shaft.

Reference dimension for input shaft:

- Maximum deviation from zero — -0.05...0.00 mm (-0.002...0.00 in)

- Fully assembled length — 138.55...138.60 mm (5.455...5.457 in)

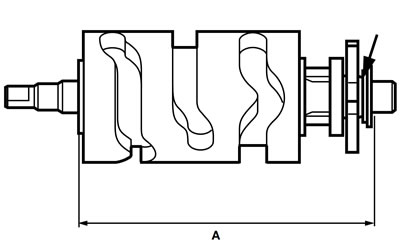

Checking/adjusting fully assembled length of selector drum

- Place spacing washer and both thrust washers on the selector drum.

- Using slide gauge, determine fully assembled length "A".

- If necessary, adjust fully assembled length "A" with a shim (arrow).

Fully assembled length:

- Selector drum — 111.80...111.90 mm (4.402...4.406 in)

Shimming selector shaft

Caution: If the housing or the complete selector shaft is replaced, the selector shaft must be measured and shimmed.

- Measure distance "A" from shouldered bushing to cover mating face.

- Measure distance "B" from shouldered bushing to housing mating face.

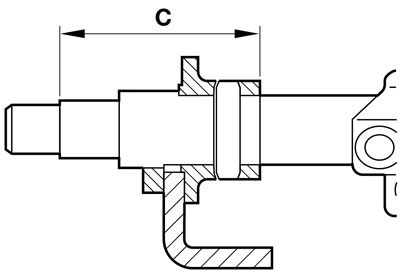

- Measure distance "C" from the shoulder on the selector shaft to the back of the sleeve.

- Calculate endplay as follows:

- Distances "A" + "B" = "D"

- Distances "D" - "c" = "E"

- Distance "E" - thickness of spacing washer = endplay.

Endplay:

- Selector shaft — 0.1...0.3 mm (0.004...0.012 in)