Troubleshooting

Warning: The Troubleshooting section of this manual is a guide to diagnose problems. Read the appropriate sections of this manual before performing any work. Improper repairand/or maintenance could result in death or serious injury.

Warning: Do not loosen or remove pressure cap when engine is hot. The cooling system is under pressure and hot coolant and steam can escape from pressure cap, which could cause severe burns. Allow engine to cool before servicing the cooling system.

Low Engine Temperature

- Thermostat stuck open.

High Engine Temperature

- Thermostat stuck closed.

- Blocked hoses, pipes or passages.

- Restricted air flow through radiator.

- Defective cooling fan.

- Faulty coolant pump.

- Low coolant level.

- Air in system.

- Defective pressure cap.

- Defective engine coolant sensor.

Coolant Leaks

- Pressure cap not properly installed.

- Damaged pressure cap gasket.

- Deteriorated О-rings on coolant pump or manifolds.

- Leaking hose or hose connection.

Pressure cap test

| PART NUMBER | TOOL NAME |

| HD-45335 | COOLANT SYSTEM PRESSURE TESTER |

Test pressure cap for correct operating range when changing antifreeze or any time cooling system maintenance is performed.

1. Remove pressure cap.

2. Inspect gasket and springs of cap for wear and damage.

Note: Wet cap upper sealing gasket before installing onto adapter.

3. See Figure 7-2. Connect COOLANT SYSTEM PRESSURE TESTER (Part No. HD-45335) to pressure cap.

4. Pump handle until pressure valve in cap opens.

5. Replace pressure cap if:

- a. Vents below low limit, 124 kPa (18 psi).

- b. Vents above high limit, 152 kPa (22 psi).

- c. Pressure falls rapidly when pressurized within range.

6. Remove adapter and cap.

Figure 7-2. Pressure Cap Test

System pressure test

| PART NUMBER | TOOL NAME |

| HD-45335 | COOLANT SYSTEM PRESSURE TESTER |

1. Lift rear of fuel tank. Lift rear of fuel tank.

2. Verify that coolant is at proper level. See Coolant of cooling system.

3. Remove filler cap.

4. Clean and inspect filler neck, upper and lower sealing seats, overflow tube and overflow tank.

Note: Wet the upper sealing surfaces before installing adapter onto tester head.

5. Connect COOLANT SYSTEM PRESSURE TESTER (Part No. HD-45335) to filler neck (2).

Note: Never exceed upper limit rating of pressure cap. Excessive pressure can rupture cooling pipes, hoses and radiator.

6. Pump tester until pressure reaches 138 kPa (20 psi).

7. Observe pressure gauge and proceed as indicated in Table 7-5.

8. Release system pressure before removing tester from filler neck.

Table 7-5. System Pressure Test

| NEEDLE MOVEMENT | LEAK | ACTION |

| Holds steady for 2 minutes | None | None |

| Drops slowly | Small | Dye test |

| Drops quickly | Major | Visual |

Freeze point test

| PART NUMBER | TOOL NAME |

| HD-23688 | COOLANT TESTER (F) |

| HD-26568 | COOLANT TESTER (C) |

1. Remove pressure cap.

2. Place a few drops of coolant from the filler neck of the radiator on the prism of either the COOLANT TESTER (C) (Part No. HD-26568) or the COOLANT TESTER (F) (Part No. HD-23688).

3. Hold the prism up to a light.

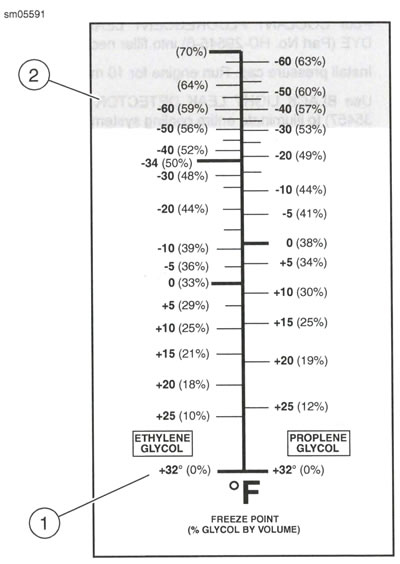

4. See Figure 7-3. The coolant freeze point is the mark on the ETHYLENE GLYCOL temperature scale (1) where the dark area (2) begins.

Warning: Coolant mixture contains toxic chemicals, which may be fatal if swallowed. If swallowed, do not induce vomiting; call a physician immediately. Use in a well ventilated area. Irritation to skin or eyes can occur from vapors or direct contact. In case of skin or eye contact, flush thoroughly with water and go to hospital, if necessary. Dispose of used coolant according to federal, state and local regulations

Notice: Use only Genuine Harley-Davidson Extended Life Antifreeze and Coolant. Use of other coolants/mixtures may lead to engine damage.

5. Compare the freeze point of the coolant to the anticipated operating or storage temperatures. Replace as required. See Coolant of cooling system.

- a. If the indicated freeze point is less than specified on the container, replace with GENUINE HARLEY-DAVIDSON EXTENDED LIFE ANTIFREEZE & COOLANT (HD-99822-02).

- b. To match anticipated cold temperatures that exceed that specified for the Harley-Davidson antifreeze, replace with a mixture of de-ionized water and undiluted ethylene glycol according to the directions on the container of the undiluted ethylene glycol.

6. Replace the pressure cap.

Figure 7-3. Coolant Tester Calibration Scale (Fahrenheit): 1. Ethylene glycol scale 2. Dark area

Leak detection dye test

| PART NUMBER | TOOL NAME |

| HD-29545-6 | COOLANT FLUORESCENT LEAK DETECTION DYE |

| HD-35457 | BLACK LIGHT LEAK DETECTOR |

1. Lift rear of fuel tank. Lift rear of fuel tank

2. Verify that coolant level is at proper level. See Coolant of cooling system.

3. Remove filler cap.

4. Remove an amount of coolant equal to the amount of dye being used.

5. Pour COOLANT FLUORESCENT LEAK DETECTION DYE (Part No. HD-29545-6) into filler neck.

6. Install pressure cap. Run engine for 10 minutes.

7. Use BLACK LIGHT LEAK DETECTOR (Part No. HD-35457) to illuminate entire cooling system. A yellow fluorescence indicates a leak.

8. Inspect engine oil for yellow dye.

Note: Dye in oil indicates a possible damaged engine head gasket. Drain and replace contaminated oil.

Tests for leaking gasket

| PART NUMBER | TOOL NAME |

| HD-45335 | COOLANT SYSTEM PRESSURE TESTER |

Perform the following tests if a leak exists but no evidence of a leak is found.

1. Start and run cold engine.

- a. White smoke from exhaust system indicates a blown gasket.

2. Run engine. Shut off engine.

- a. Remove oil level dipstick. Light-colored foam on dipstick indicates a blown gasket.

- b. Open oil drain plug. Drain a small amount of oil. Water or coolant drains out first if gasket is blown.

3. Install COOLANT SYSTEM PRESSURE TESTER (Part No. HD-45335).

Warning: Disconnecting spark plug cable with engine running can result in electric shock and death or serious injury.

Notes:

- Do not allow pressure to build up past maximum for system. If pressure rises past maximum, turn off engine and turn butterfly pressure valve perpendicular to tester head to release pressure.

- Do not continue to run engine unattended with COOLANT SYSTEM PRESSURE TESTER installed. There is no safety valve with the pressure cap removed and the COOLANT SYSTEM PRESSURE TESTER installed.

4. Start cold engine and idle engine to normal operating temperature.

- a. If gauge indicates fast pressure buildup, a gasket is leaking.

- b. If pressure does not build up immediately, pump the tester to 138 kPa (20 psi).

- c. If gauge needle vibrates, the cylinder head gasket for that cylinder leaks. Replace head gasket.

- d. Turn off engine. Disable one spark plug at the coil, turn ON engine. Repeat for other cylinder. The needle stops vibrating when spark is removed from leaking cylinder.

Note: Always replace engine oil after replacing cylinder head gasket.