Cylinder Compression Measurement

Note: Use the battery which is fully charged.

- Warm up the engine thoroughly.

- Stop the engine.

Remove:

- Fuel Tank (See Fuel Tank Removal in the Fuel System (DFI) chapter)

- Air Cleaner Housing (See Air Cleaner Housing Removal in the Fuel System (DFI) chapter)

- Stick Coils (See Stick Coil (Ignition Coil together with Spark Plug Cap) Removal in the Electrical System chapter)

- Spark Plugs (See Spark Plug Replacement in the Periodic Maintenance chapter)

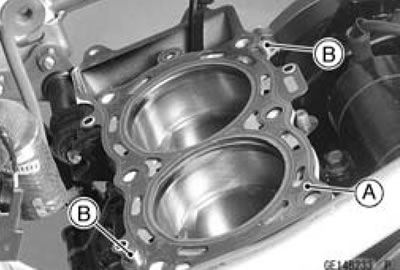

- Attach the compression gauge [A] and adapter [B] firmly into the spark plug hole.

Using the starter motor, turn the engine overwith the throttle fully open until the compression gauge stops rising; the compression is the highest reading obtainable.

Special Tools - Compression Gauge, 20 kgf/cm²: 57001-221

Compression Gauge Adapter, M10 x 1.0: 57001-1317

Cylinder Compression

Usable Range: 1 226-1 844 kPa (12.5-18.8 kgf/cm², 178-267 psi) at 425 r/min (rpm)

- Repeat the measurement for the other cylinders.

- Install the spark plugs (See Spark Plug Replacement in the Periodic Maintenance chapter).

The following table should be consulted if the obtainable compression reading is not within the usable range.

| Problem | Diagnosis | Remedy (Action) |

| Cylinder compression is higher than usable range | Carbon accumulation on piston and in combustion chamber possibly due to damaged valve stem oil seal and/or damaged piston oil rings (This may be indicated by white exhaust smoke). | Remove the carbon deposits and replace damaged parts if necessary. |

| Incorrect cylinder head gasket thickness | Replace the gasket with a standard part. | |

| Cylinder compression is lower than usable range | Gas leakage around cylinder head | Replace damaged gasket and check cylinder head warp. |

| Bad condition of valve seating | Repair if necessary. | |

| Incorrect valve clearance | Adjust the valve clearance. | |

| Incorrect piston/cylinder clearance | Replace the piston and/or cylinder. | |

| Piston seizure | Inspect the cylinder and replace/repair the cylinder and/or piston as necessary. | |

| Bad condition of piston ring and/or piston ring grooves | Replace the piston and/or the piston rings. |

Cylinder Head Removal

- Drain the coolant (See Coolant Change in the Periodic Maintenance chapter).

Remove:

- Exhaust Pipes (See Exhaust Pipe Removal)

- Cylinder Head Cover (See Cylinder Head Cover Removal)

- Camshafts (See Camshaft Removal)

- Throttle Body Assy (See Throttle Body Assy Removal in the Fuel System (DFI) chapter)

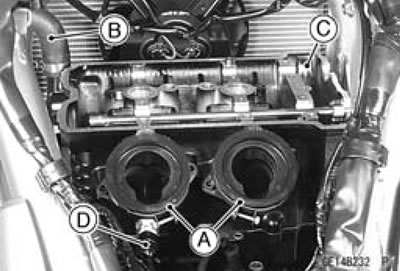

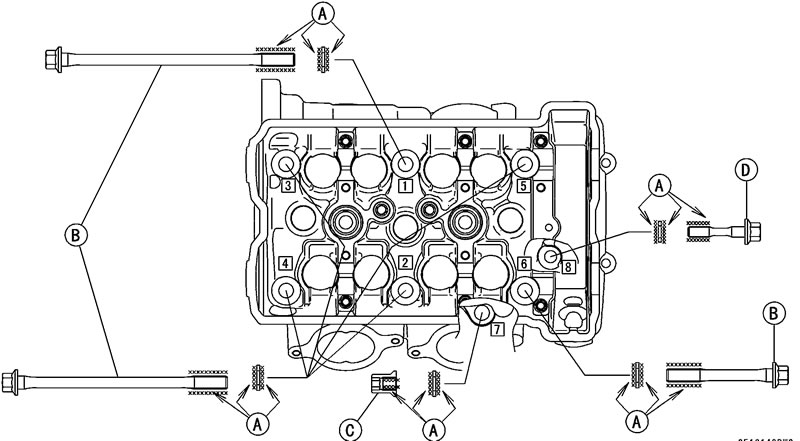

- Throttle Body Assy Holders [A] (See Throttle Body Assy) Holder Removal)

- Left Front Frame Cover (See Front Frame Cover Removal in the Frame chapter)

- Water Hose [B]

- Front Camshaft Chain Guide [C]

- Water Temperature Sensor Connector [D]

- Remove the cylinder head and cylinder bolts, following the specified sequence.

Firstly remove the M6 cylinder head bolts and M6 cylinder bolts [A].

- Secondly, remove the M8 bolts [B].

- Thirdly, remove the M10 nut [C].

- Lastly, remove the M10 bolts [D].

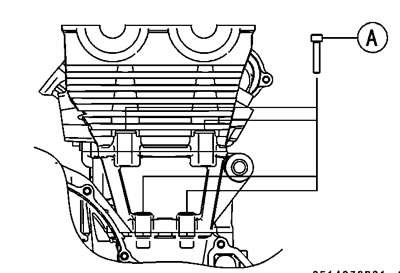

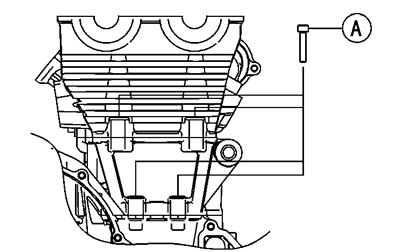

- Take off the cylinder head [A] from the space of the frame pipes.

Cylinder Head Installation

Note: The camshaft cap is machined with the cylinder head, so if a new cylinder head is installed, use the cap that is supplied with the new head.

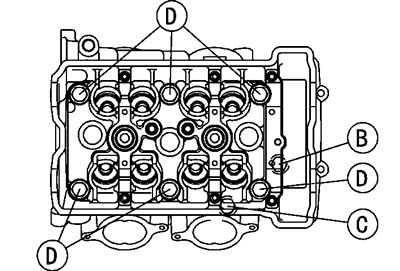

- Install a new cylinder head gasket [A] and dowel pins [B].

- Apply molybdenum disulfide oil solution [A] to both sides of washers and the threads of bolts and nut.

- M10 Cylinder Head Bolts [B]

- M10 Cylinder Nut [C]

- M8 Cylinder Bolt [D]

- Tighten the all the bolts and nut following the tightening sequence [1-8].

Torque - Cylinder Head Bolts (M10):

- First: 25 Nm (2.5 kgf·m 18 ft·lb)

- Final: 56 Nm (5.7 kgf·m 41 ft·lb)

- Cylinder Nut (M10): 49 Nm (5.0 kgf·m, 36 ft·lb)

- Cylinder Bolt (M8): 27.5 Nm (2.8 kgf·m, 20 ft·lb)

Note: The tightening sequence No.1-No.5 are the cylinder head bolts that are tightened between the cylinder head with the crankcase. The No.6 is the cylinder head bolt that is tightened between the cylinder head with the cylinder. The No.7 and No.8 are the cylinder nut and cylinder bolt that are tightened between the cylinder and the crankcase.

- Tighten the M6 cylinder head bolts and M6 cylinder bolts [A].

Torque - Cylinder Head Bolts (M6): 12 N·m (1.2 kgf·m, 106 in·lb)

Cylinder Bolts (M6): 12 Nm (1.2 kgf·m, 106 in·lb)

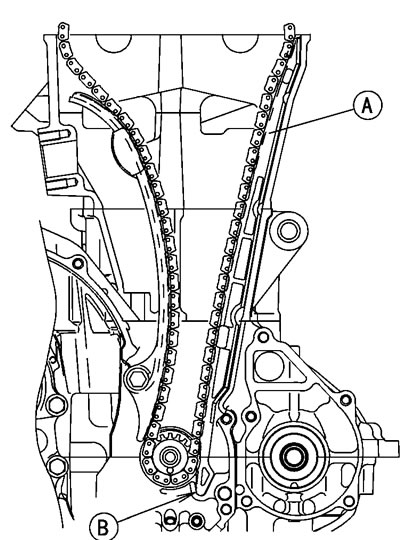

- Install the front camshaft chain guide [A].

lnsert the end [B] of front camshaft chain guide into the hollow on the lower crankcase half.

- Install the removed parts (see appropriate chapters).

Cylinder Head Warp

- Clean the cylinder head.

- Lay a straightedge across the lower surface of the cylinder head at several positions.

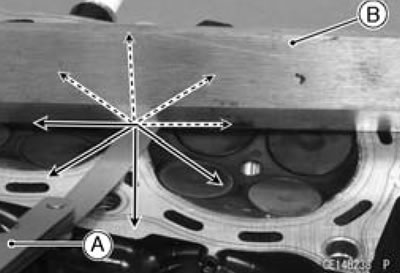

- Use a thickness gauge [A] to measure the space between the straightedge [B] and the head.

Cylinder Head Warp

Standard:

Service Limit: 0.05 mm (0.002 in.)

If the cylinder head is warped more than the service limit, replace it.

If the cylinder head is warped less than the service limit, repair the head by rubbing the lower surface on emery paper secured to a surface plate (first No. 200, then No. 400).