Fork oil leak check

Fork Oil Seals

The fork oil seal is designed to allow a fine film of oil to lubricate the fork sliding surface.

- The oil film is more visible after continuous high-speed compression and rebound movement.

- Due to greater lubrication needs, larger forks have a greater amount of oil film than smaller forks.

Oil Leak Check

1. Observe oil-ring.

2. Wipe fork clean.

3. Ride motorcycle over bumpy road or complete 5-6 braking events.

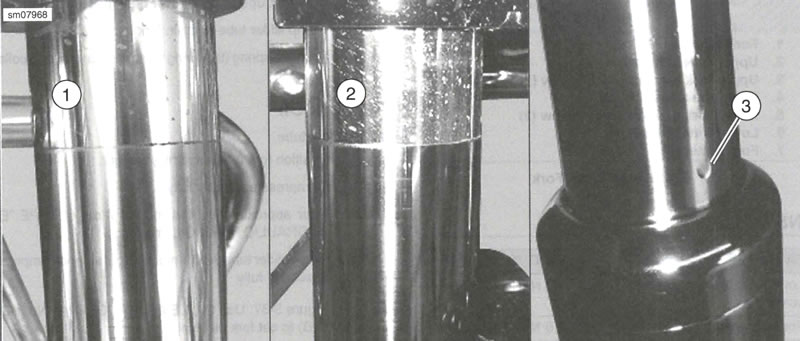

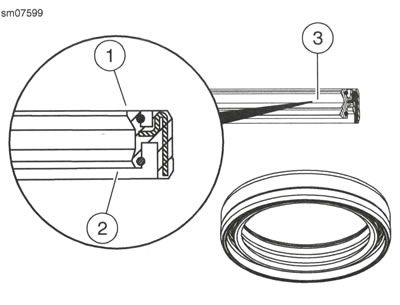

4. See Figure 3-35. Check fork slider tube for oil.

- a. If a normal oil/dust film (1, 2) is present, there is no leak.

- b. If an oil run or drip (3) is present, perform procedure two or three more times to confirm oil leak.

Figure 3-35. Front Forks: 1. Normal oil/dust film; 2. Normal oil/dust film; 3. Drip

Prepare

1. Remove main fuse. See Power disconnect.

2. Remove front wheel. See Front wheel.

3. Remove front fender. See Front fender.

4. Remove headlamp fairing. See Headlamp fairing.

5. Remove and set aside front brake caliper. See Front brake caliper.

6. Remove front turn signal lamps. See Front turn signal lamps.

Remove

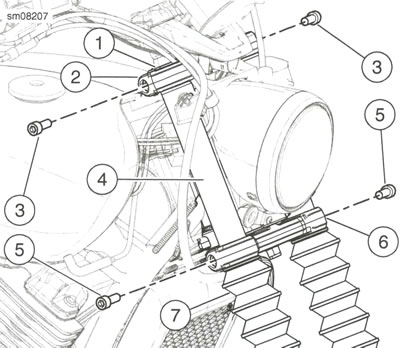

1. See Figure 3-36. Remove front fork tube assemblies.

- a. Loosen the upper fork bracket pinch screws (3).

- b. Loosen the fork tube caps (1).

- c. Loosen the lower fork bracket pinch screws (5).

- d. Remove fork tube assemblies (4) from fork brackets (2, 6).

Figure 3-36. Front Fork: 1. Fork tube cap (2); 2. Upper fork bracket; 3. Upper fork bracket pinch screw (2); 4. Fork tube assembly (2); 5. Lower fork bracket pinch screw (2); 6. Lower fork bracket; 7. Fork gaiter (2)

Install

| FASTENER | TORQUE VALUE | |

| Lower fork bracket pinch screw | 34.3-39.2 Nm | 26-28 ft·lbs |

| Fork tube cap | 24.5-28.5 Nm | 18-21 ft·lbs |

| Upper fork bracket pinch screw | 50.0-60.0 Nm | 37-44 ft·lbs |

1. See Figure 3-36. Install front fork tube assemblies.

- a. Insert each fork tube assembly (4) through lower fork bracket (6) and upper fork bracket (2).

- b. Verify top of fork tube is flush with top of upper fork bracket.

- c. Install lower fork bracket pinch screws (5). Tighten to 34.3-39.2 Nm (26-28 ft·lbs).

- d. Tighten fork tube caps (1) to 24.5-28.5 Nm (18-21 ft·lbs).

- e. Install upper fork bracket pinch screws (3). Tighten to 50.0-60.0 Nm (37-44 ft·lbs).

- f. Slide upper end of fork gaiter (7) up until it contacts underside of lower fork bracket.

Drain and fill forks

| PART NUMBER | TOOL NAME |

| HD-59000-B | OIL LEVEL GAUGE |

| FASTENER | TORQUE VALUE | |

| Fork tube cap | 24.5-28.5 Nm | 18-21 ft·lbs |

Drain Fork Oil

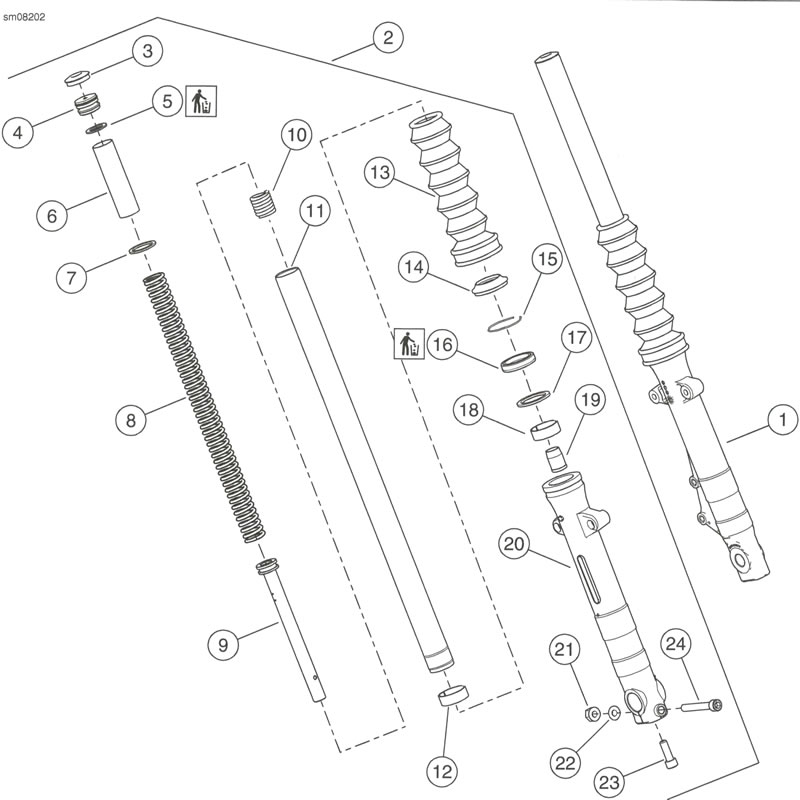

1. See Figure 3-38. Drain fork tube.

- a. Remove cover (3).

- b. Remove fork tube cap (4) from slider tube (11). Discard O-ring (5).

- c. Turn fork upside down over drain pan.

- d. Pump slider tube to drain fork oil.

- e. Remove spring (8), spring washer (7) and spring collar (6).

Fill Fork Oil

1. Fill fork tube.

- a. Position fork tube assembly upright.

- b. Compress assembly fully.

- c. Pour approximately 414 mL (14 fl oz) of TYPE "E" HYDRAULIC FORK OIL into fork.

- d. Pump slider tube 8-10 times to expel air and compress assembly fully.

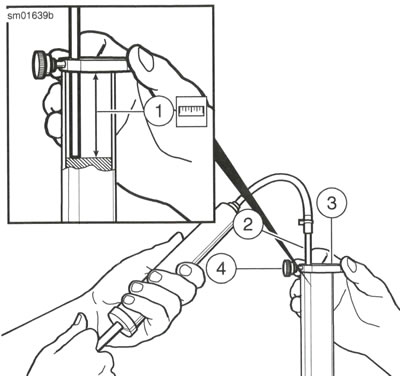

2. See Figure 3-37. Use OIL LEVEL GAUGE (Part No. HD-59000-B) to set fork oil level.

- a. Adjust length of draw off tube to fork oil level specification (1). Refer to Table 3-6.

- b. Lock tube (2) to collar (3) with thumb lock (4).

- c. Fit collar to fork tube.

- d. Draw off excess oil.

3. See Figure 3-38. Install spring (8), spring washer (7) and spring collar (6).

4. Install fork tube cap.

- a. Apply HARLEY-DAVIDSON SEAL GREASE to new O-ring.

- b. Install new O-ring (5) on fork tube cap (4).

- c. Install fork tube cap into slider tube (11). Tighten to 24.5-28.5 Nm (18-21 ft·lbs).

5. Install cover (3).

Figure 3-37. Oil Level Gauge: 1. Fork oil level; 2. Tube; 3. Collar; 4. Thumb lock

Disassemble

1. Drain front fork tube. See Front fork, Drain and Fill Forks.

2. See Figure 3-38. Disassemble fork leg.

- a. Remove fork gaiter (13).

- b. Remove dust seal (14).

- c. Remove internal circle clip (15)

- d. Remove screw (23) from bottom of slider (20).

- e. Withdraw slider tube (11) from slider.

- f. Remove fork seal (16), spacer (17) and upper bushing (18). Discard fork seal.

- g. Insert a small diameter rod through opening in bottom of slider tube to remove damper tube (9).

- h. Remove damper tube and rebound spring (10) from slider.

- i. Remove lower bushing (12) from slider tube.

Figure 3-38. Front Fork Assembly: 1. Left side fork leg assembly; 2. Right side fork leg assembly; 3. Cover; 4. Fork tube cap; 5. O-ring; 6. Spring collar; 7. Spring washer; 8. Spring; 9. Damper tube; 10. Rebound spring; 11. Slider tube; 12. Lower bushing; 13. Fork gaiter; 14. Dust seal; 15. Internal circle clip; 16. Fork seal; 17. Spacer; 18. Upper bushing; 19. Sleeve; 20. Slider; 21. Nut; 22. Washer; 23. Screw; 24. Pinch bolt

Clean and inspect

1. Clean all parts thoroughly. Verify that slider tube and slider tube bore is clean and dry.

2. Inspect all parts for wear or damage. Replace as necessary.

Assemble

| PART NUMBER | TOOL NAME |

| HD-51462 | FORK SEAL AND BUSHING INSTALLATION TOOL |

| FASTENER | TORQUE VALUE | |

| Fork slider tube screw | 14.9-24.4 Nm | 11-17 ft·lbs |

1. See Figure 3-38. Install lower bushing (12) onto slider tube (11).

2. Install rebound spring (10) over damper tube (9).

3. Install damper tube and rebound spring into slider tube.

4. Insert spring (8), tight wound end first into slider tube.

5. Push damper tube through opening at bottom of slider tube using spring.

6. Install slider tube into slider (20). Install screw (23) through bottom of slider. Hand-tighten.

7. Move slider tube through its full range of travel several times to verify proper component alignment.

8. Apply downward force on spring and tighten screw to 14.9-24.4 Nm (11-17 ft·lbs).

9. Remove spring.

10. Install upper bushing (18) over slider tube and into slider.

11. Install spacer (17) over slider tube and into slider.

12. Place FORK SEAL AND BUSHING INSTALLATION TOOL (Part No. HD-51462) over slider tube.

13. Seat upper bushing into slider bore by tapping spacer downward with installation tool.

14. Remove fork seal and bushing installation tool.

15. See Figure 3-39. Coat lips (3) and inner diameter of fork seal with HARLEY-DAVIDSON SEAL GREASE.

16. See Figure 3-38. Install new fork seal (15) (lettering side up) over slider tube.

17. Place fork seal and bushing installation tool over slider tube.

18. Seat fork seal into slider bore by tapping oil seal downward with installation tool.

19. Remove fork seal and bushing installation tool.

20. Install internal circle clip (15) into groove in top of slider bore.

21. Install dust seal (14).

22. Install fork gaiter (13).

23. Fill fork tube with oil. See Front fork, Drain and Fill Forks.

Figure 3-39. Fork Seal: 1. Top (lettering side); 2. Bottom; 3. Lips

Complete

1. Install front turn signal lamps. See Front turn signal lamps.

2. Install front brake caliper. See Front brake caliper.

3. Install headlamp fairing. See Headlamp fairing.

4. Install front fender. See Front fender.

5. Install front wheel. See Front wheel.

6. Install main fuse. See Power disconnect.